Accommodation of expansion in a scratch coat? Yes, but in the wrong places

Ceramics cant be adhered directly on the sub-floor itself as wood does not bond to cementious produces well, so a substrate between them is used. Today, the choices for that substrate is either a scratch coat, a backerboard (which is a layer of 1/4″ cement or fibre cement board), or an uncoupling membrane. Since there is a substrate between the structure and the tiles, we basically have two different bonding planes (goals) for a ceramic tile install.

1: From the ceramic tile to the bonding substrate.

2: From the bonding substrate to the sub-floor

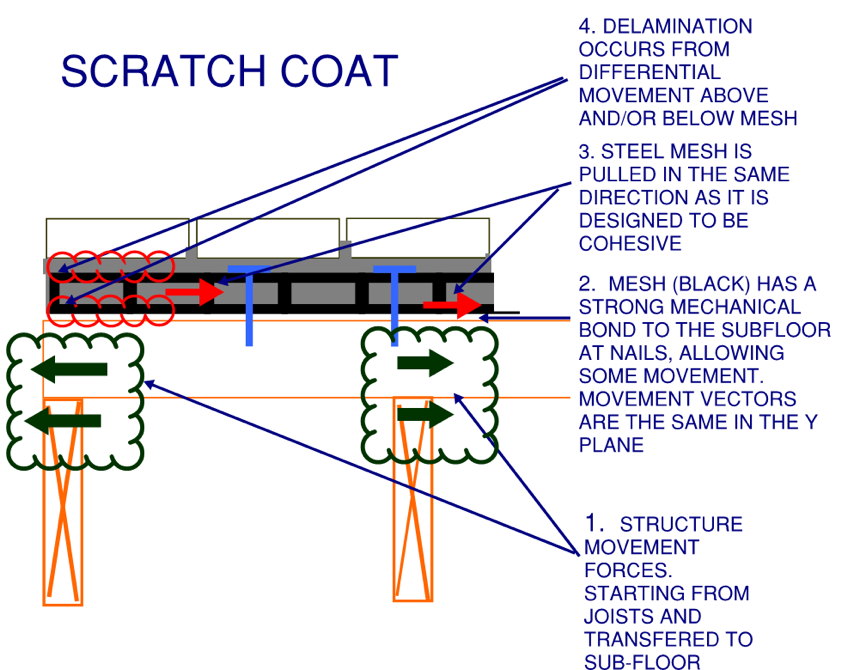

The steel mesh of the scratch coat handles expansive forces quite well in terms of the substrate adhering to the structure, however that is not the main goal of using a substrate. The goal is not for maximum adhesion, but rather good compatibility. If the structure moves in different directions (see figure above), then the steel mesh moves in tune with that structure (1). However the movement in the structure is not uniform, and the steel mesh has a mechanical bond through the nails into the plywood, which provides some movement accommodation which is good (2). Since the steel mesh is designed to handles expansive forces well, it is cohesive to itself and moves uniformly (3). To better illustrate this cohesiveness, the steel by itself will never fail by splitting in two, or bending. This is the common error that people make, thinking because the mesh can handle expansive forces, that it handles the expansive forces we need. We don’t really care how well the steel does, we care about how the steel affects the tile and mortar that is around it. The mesh is a double edged sword, as this cohesiveness allows the mesh to move differentially to the tile and to the plywood (4). Delamination occurs on bonding goal #1 and/or #2.

The nails in this scenario are what allow only a slight amount of movement. One may think that more nails are needed to fix this problem of tiles cracking, but more nails do not improve compatibility. Reducing the bending moment (flex) of the floor by adding another sheet of plywood is what helps improve compatibility.

In a perfect world, the physical properties of the house will never change, but we don’t live in such a world. Whatever movement can’t be accommodated by bonding goal #2, the result will have to be transferred to the next layer, which is the ceramic tile and the grout. As we know, ceramics can’t accommodate movement well and shatter or delaminate. This is why cracks do happen.

Cement backer board: more of the same

I don’t have proof (yet) of this therory, but this is why I believe a floor would fair no better with backerboard.

Cement backer board installs are really more of the same thing. It is difficult to say whether the result will be slightly better or worse than a scratch coat as the composition is different, but the basic mechanics are the same. The 1/4″ cement board or fibre-cement board has the same physical limitations as the scratch coat. It is essentially cement that is mechanically attached to the joists with no accommodation for movement. I personally would not be surprised if this is worse than scratch coat install as nails that are not driven in the floor completely tend to bend which is a good thing, where as a screwed down fibre-cement board looses the slight advantages of the movement of that nail.

This is the preferred method

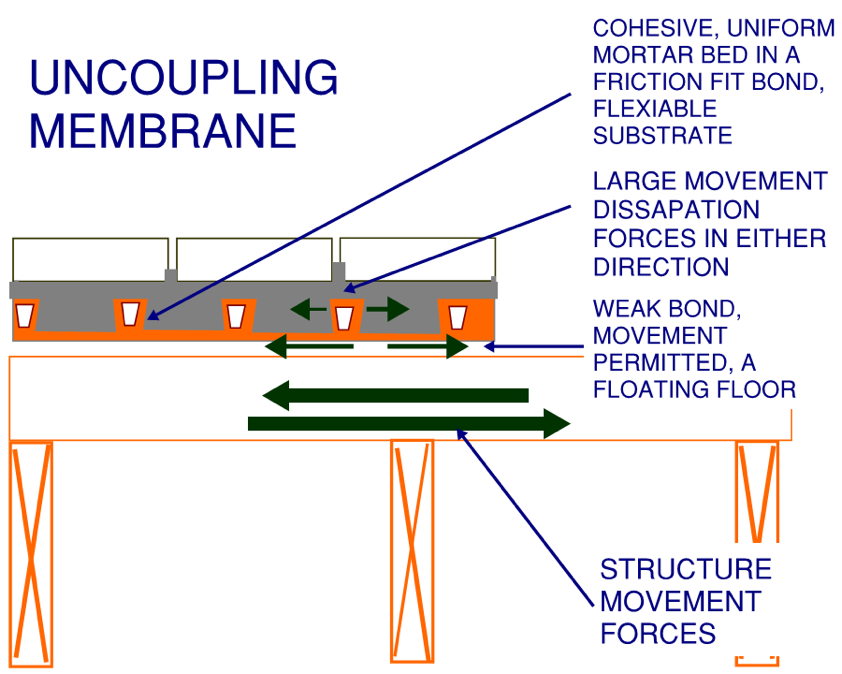

An uncoupling membrane has an opposite philosophy than the scratch coat. Rather than making the bonding substrate (uncoupling membrane) firm to the plywood, the bond is intentionally very weak to encourage movement where it is wanted rather than discouraging it altogether. The uncoupling membrane can slide over the plywood. Bonding goal #2 intentionally allows movement.

For the connection to the ceramic tile, the thin set mortar is not so much bonded but friction fitted in place (thinset does not bond to polyethylene plastic). A good analogy I can think of is how your socks bond to your leg. The elastic allows a tight fit, but those socks never pierce your skin, or you have bigger problems than the composition of your floor. This is a good type of fit because if your leg were to get slightly thicker because you have increased muscle mass, the sock’s elastic movement would still accommodate that larger leg and still fit. But most important, the shape of the ceramic remains uniform, so the ceramic floor “sheet” never changes and any movement is transferred to the uncoupling membrane to deform intentionally. This system is essentially a floating floor.

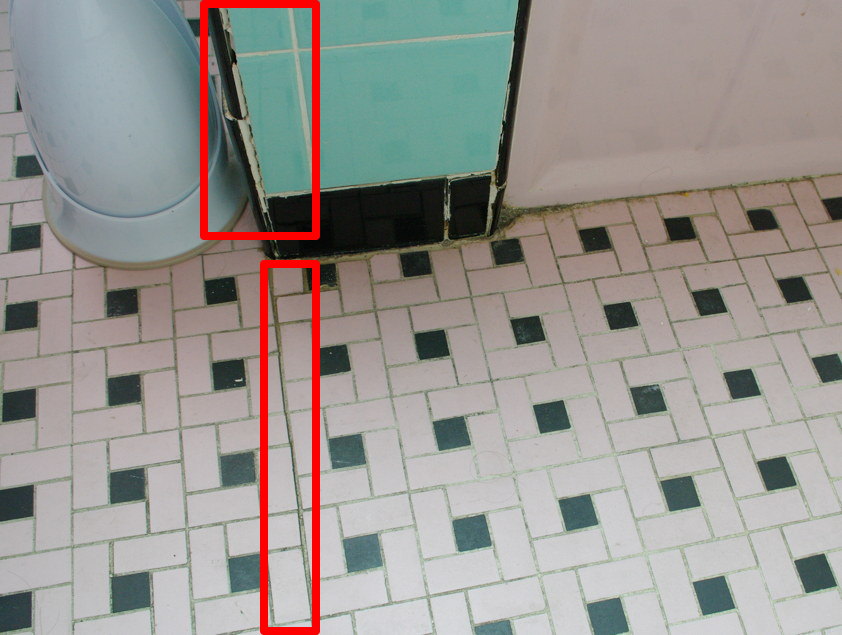

The failed scenario, a scratch coat victim

Granted, the age of this ceramic floor is older than me, but it is not really an excuse. I couldn’t tell you how old the crack is, but it shouldn’t really matter. The bathroom is not used much luckily, or water would have definitely seeped through the cracks and rotted the floor boards long ago. The extent of the damage at this time is unknown, but is structurally sound.

- Don’t use scratch coat in any ceramic tile installation

- Check sub-floor thickness and material type before any installation. Many subfloors are simply inadequate for preventing movement against ceramic tile

- Backerboard installs are have the same pitfalls as scratch coats

- Schluter Ditra works well, however other manufacturers are good too. Schulter has excellent customer support, which is what you want your contractor needs

Builder of my house installed ceramic tiles in the corridor(~400 sq ft) using wire mesh scratch coat method in 1987. They are still solid, none has lifted or cracked, my only problem is, I would like to have them replaced with bigger tiles(12″x24″). Since I have already witnessed the durablity and reliability of scratch coat method, I will not hesitate to use scratch method again. I only hope I can find someone willing to take this challenge, and push a product(Ditra) with only few years of usage.

That is good news. Not every install is a failure, there are so many forces at work and it is possible your subfloor is more stable than others and the installers may have done a good job during the install. Using a scratch coat again on your floor may be safe for another 30 years. Not every homeowner has the long term familiarity with their own home and may consider the risk to be higher.

Remember that two different people may look at the same glass and determine it is either half empty or half full. Some people will feel comfortable with the risk and other will not on the same floor.

Uncoupling membranes have been around in some markets for almost 30 years and they do last a long time too.

Scratch coat is not definitively going to fail. It is just not the best practice anymore and there is no reason to take a risk who spending a lot of money in my opinion

I have been informed by one of the big box retailers that the up and coming product to replace the mesh/thin coat method is a product called RedGard. I am looking to install tiles in a first floor bathroom (not on concrete as in basement).

it will be interesting to see how this product will pan out over time. Custom building products is a reputable company, but even reputable companies pull new products after a short time, so it is not a shoe in

Redguard is a waterproofing not a substraight