Big box store paints have appealing advantages to the average homeowner. Yes, it is convenient to have all the items you need in one store. At approximately $30-$40 per gallon for a supposedly top tier paint, the prices are competitive without question. But on closer inspection, this deal is probably not so great. I would like to point out at this time that many people, couldn’t careless about the quality of paint on their walls. I think this is the case for good reason….who is really going to notice it? It’s a fair question. A better question is “Is someone else going to notice it?”. It is curious characteristic of human nature that we only notice how bad something is when someone else points it out to you. If you prefer your bliss, read another article. If you to take bite of fruit from the paint tree of knowledge, read on. Disclaimer: painted fruit tastes funny, and is harmful to your health. Don’t bite it. They belong on fridges pained by your niece or art by Paul Cézanne.

The one coat solution. Why paint twice when you can paint only once?

It is appealing for sure. Who in their right mind would choose to paint a room twice when you could do it once? Honestly those people are suckers. You could easily make fun of them for being out of touch with the latest paint technology. “You paint a room like my grandparents, with lead!”. Our culture is fixated on performing tasks faster whatever they may be. The tag line goes something like “would you rather spend more quality time with your kids than painting?”. It’s a fair point. Can we really paint walls with only one coat, when we can paint it with two?. Somewhere the idea was lost that maybe painting a room with your kids is better than for your kids. Lets focus on the paint facts instead on what is ideally right. If one coat is better that’s fine. So let’s see if it is actually possible.

Here is the truth, paint, such as it is and how it is applied on walls today, with rollers, brushing and spraying will never…ever…be able to be applied effectively in one coat. This has nothing to do with the chemical composition of the paint formula at all. It has to do about the laws of physics, and the maximum thickness possible for one layer of paint before it gets too thick, and starts dripping off the wall.

Texture

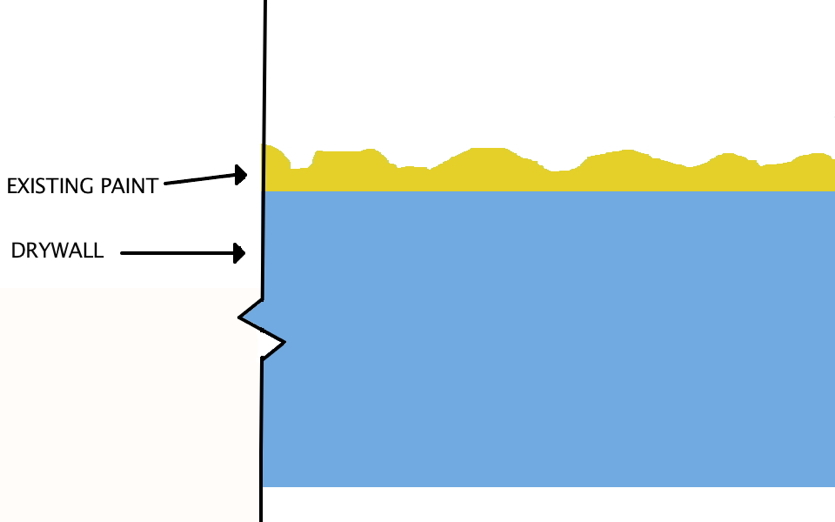

Every wall you are going to paint has a texture that is not smooth as enamel or paint on car. It is rough in texture, and has many crests and valleys. This is a normal texture for a wall. Below is a standard wall up close. You can see the texture, and notice when a light is pointed almost parallel to the wall, the contrast is increased and you can really see the crests and valleys.

This texture is even created on new drywall when the first coat of primer is applied. Lets take a look at the existing conditions. The following pictures is what the paint looks like if we look at the thickness of the materials only. We will view a section through the wall in plan view (birds eye). Notice that the tan/yellow coloured paint has crests and valleys like the previous picture.